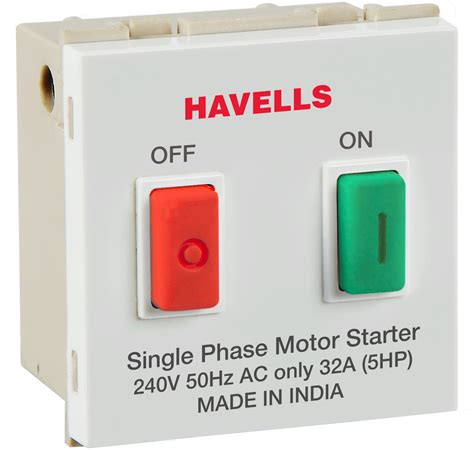

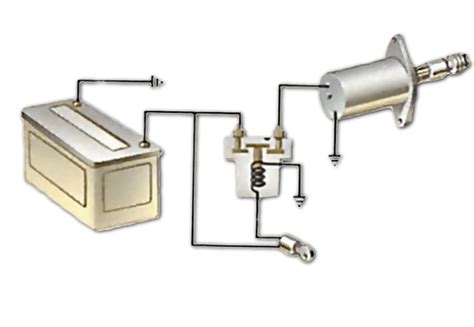

It’s important to always keep the starter switch key in your pocket during the pre-trip inspection. This is because there’s a chance that someone could move the vehicle while you’re checking underneath it, which could be dangerous. By keeping the key with you, you can ensure that the vehicle won’t be started accidentally or without your knowledge. This simple precaution can help prevent accidents and keep you safe on the road.

Why put the starter switch key in your pocket during the vehicle inspection for CDL?

Rewritten paragraph:

Question: Why is it important to keep the starter switch key in your pocket during the pre-trip inspection?

Answer: The reason for this is to prevent anyone from accidentally moving the vehicle while you are inspecting underneath it. By keeping the key with you, you have control over the vehicle and can ensure that it remains stationary during the inspection process. This is a crucial safety measure that helps to prevent accidents and injuries, and it is recommended that all drivers follow this practice when conducting pre-trip inspections.

Where should the ignition key be during the pre-trip inspection CDL?

A great way to reduce stress levels is through the practice of meditation. Meditation has been shown to have numerous benefits for both the mind and body, including reducing anxiety, improving sleep quality, and increasing feelings of well-being. One study found that regular meditation can even lead to changes in the brain that help individuals better cope with stress. By taking just a few minutes each day to meditate, you can experience these benefits and feel more relaxed and centered in your daily life.

And with the convenience of meditation apps and online resources, it’s easier than ever to incorporate this practice into your routine.

What is the most important reason for doing a vehicle inspection CDL?

“`Inspecting your vehicle is crucial for ensuring safety on the road, not just for yourself but for other drivers as well. By identifying any defects during an inspection, you can prevent potential problems from arising later on. Safety should always be the top priority when it comes to vehicle maintenance.“`

Which of the following is the most important reason for doing a pre-trip inspection?

“`Performing a pre-trip inspection is crucial for ensuring your safety on the road. Neglecting to inspect your load, brakes, wiring, and other components can lead to dangerous situations while driving. It’s essential to take the time to thoroughly check your vehicle before hitting the road to prevent any potential accidents or breakdowns. By prioritizing safety through pre-trip inspections, you can have peace of mind and a smoother driving experience.

“`

How do you memorize a pre-trip inspection?

“`Memorizing a pre-trip inspection can be a daunting task, but there are a few techniques that can help. First, break the inspection down into smaller parts and focus on memorizing each section separately. Use visual aids, such as diagrams or pictures, to help you remember the different parts of the inspection. Another helpful technique is to practice the inspection regularly, either by physically going through the steps or by reciting them out loud.

Repetition is key when it comes to memorization. Additionally, try to associate each step with a specific action or image to help solidify it in your memory. Finally, don’t be afraid to ask for help or guidance from a more experienced driver or instructor. With practice and dedication, you can

What are the 7 steps of inspection process?

The 7 steps of inspection process are: planning, preparation, notification, entry, inspection, documentation, and follow-up. Planning involves identifying the scope and purpose of the inspection. Preparation includes gathering information and resources needed for the inspection. Notification involves informing the parties involved about the inspection.

Entry involves gaining access to the site or facility being inspected. Inspection involves conducting a thorough examination of the site or facility. Documentation involves recording the findings and observations during the inspection. Follow-up involves communicating the results of the inspection and taking any necessary corrective actions.

These steps ensure that inspections are conducted efficiently and effectively, and that any issues or concerns are addressed in a timely manner.

What are the five 5 types of inspection?

“`There are five main types of inspection: visual inspection, dimensional inspection, surface inspection, non-destructive inspection, and functional inspection. Visual inspection involves examining an object or product with the naked eye to identify any defects or abnormalities. Dimensional inspection involves measuring the size and shape of an object to ensure it meets specifications. Surface inspection involves examining the surface of an object for defects or irregularities.

Non-destructive inspection involves using methods such as x-rays or ultrasound to inspect an object without damaging it. Functional inspection involves testing an object to ensure it performs its intended function. Each type of inspection is important in ensuring the quality and safety of products and materials.“`

What are the 4 methods of inspection?

Quality control involves four distinct types of quality inspections, which are pre-production inspection, during production inspection, pre-shipment inspection, and container loading/unloading inspections. Each of these inspections serves a unique purpose in ensuring that the final product meets the required quality standards.

What are three 3 things a manager should do during an inspection?

During an inspection, a manager should first ensure that all safety protocols are being followed. This includes checking for any potential hazards or risks that could harm employees or customers. Secondly, the manager should review the cleanliness and organization of the workplace, making sure that everything is in its proper place and that the environment is conducive to productivity. Finally, the manager should communicate with employees, asking for feedback and addressing any concerns or issues that may have arisen since the last inspection.

By taking these steps, a manager can ensure that the workplace is safe, efficient, and productive.

What are the three P’s for a manager?

Performance management is a crucial aspect of any organization, and it involves addressing the three P’s: purpose, people, and process. Purpose refers to the goals and objectives that the organization aims to achieve, while people refer to the employees who work towards achieving these goals. Process, on the other hand, refers to the methods and strategies used to manage and evaluate employee performance. By addressing these three P’s, organizations can ensure that their employees are motivated, engaged, and productive, which ultimately leads to the achievement of organizational goals.

Effective performance management also helps to identify areas for improvement and provides opportunities for employee development and growth.

What must the pic do if during an inspection?

Complying with the Food Code is the primary way for a PIC to exhibit their necessary level of knowledge. Essentially, if an inspector conducts a routine inspection and discovers no violations related to foodborne illness risk factors or public health intervention, then the manager’s knowledge requirement is satisfied.

Can OSHA just show up unannounced?

It’s typical for OSHA to perform inspections without giving any prior notice. However, employers do have the right to ask compliance officers to obtain a warrant before entering the worksite. While conducting the inspection, compliance officers may identify some violations that can be fixed right away.

Can a worker be fired for calling OSHA?

According to the law, it is prohibited for an employer to take any negative action against an employee who reports safety concerns to OSHA or exercises their legal rights. If you feel that you have been subjected to retaliation in any form, it is important to file a whistleblower complaint within 30 days of the incident. This will help protect your rights and ensure that your employer is held accountable for any unlawful actions.

Can you refuse an OSHA inspection?

If someone refuses to sign in, you may wonder if you can deny them access. The answer is yes, you can. According to the Occupational Safety and Health Administration (OSHA), an employer has the right to require a Compliance Safety and Health Officer (CSHO) to obtain an inspection warrant before entering a workplace. If the CSHO does not have a warrant, the employer can refuse entry.

This is important to know as it allows employers to maintain control over who enters their workplace and ensures that inspections are conducted lawfully.

What to do if OSHA comes knocking?

If OSHA comes knocking, it’s important to remain calm and cooperative. First, ask for identification and the reason for the visit. Then, provide access to the workplace and any necessary documents. It’s important to have a designated point person to communicate with the OSHA inspector and take notes during the inspection.

If violations are found, work with the inspector to develop a plan for correcting them. It’s also important to understand your rights and responsibilities as an employer, including the right to contest any citations or penalties. Overall, being prepared and knowledgeable can help make the OSHA inspection process smoother and less stressful.

What is the primary reason for daily pre-trip inspections?

“`The primary objective of conducting pre-trip inspections is to ensure safety. By performing these inspections thoroughly, you not only safeguard yourself but also other individuals on the road. Malfunctions in your vehicle can lead to accidents, which is why it’s crucial to identify and address any issues before hitting the road.“`

What is the importance of pre-trip?

Triple-delimited paragraph:

“`Performing pre-trip inspections is crucial for ensuring the safety of both truckers and motorists on the road. Given that trucks are heavy-duty vehicles, any accidents that occur during a haul can result in fatal and long-lasting damage. For example, faulty brakes could lead to a catastrophic accident. By conducting thorough pre-trip inspections, truckers can identify and address any potential safety hazards before hitting the road.

This not only helps prevent accidents but also promotes a culture of safety and responsibility within the trucking industry.“`

Which of the following are important parts of your pre-trip inspection?

When conducting an in-cab inspection of your vehicle, it’s important to ensure that all five functions are working properly. These include the left and right turn signals, the four-way emergency flashers, the high beam/low beam headlights, and the brake lights. Begin by checking the dashboard for any warning or indicator lights. This will help you identify any potential issues before hitting the road.

What is the purpose of pre use inspection?

“`The primary objective of conducting a pre-use inspection is to guarantee the safety of the machine before operating it. A faulty machine can pose a significant threat to the operator’s life and the safety of other workers in the vicinity. Therefore, it is crucial to inspect the machine thoroughly to identify any defects or malfunctions that could compromise its safety.“`

Related Article

- Why Put Out A Fire When It’S Still Burning?

- Why Juveniles Should Not Be Tried As Adults Brain Development?

- Why It Matters That Teens Are Reading Less Answer Key?

- Why It Is Not Recommended To Transplant Carrots And Radish?

- Why Isn’T The Ink Staying In When I Tattoo?

- Why Isn’T George Strait A Member Of The Opry?

- Why Isn’T Big Chief On Street Outlaws America’S List?

- Why Is Where The Wild Things Are A Banned Book?

- Why Is Water Coming Out Of My Dishwasher Air Gap?

- Why Is There Waiting In An Infinite Source Queuing System?