There are several reasons for the current chassis shortage in the shipping industry. One major factor is the increase in global trade, which has led to a higher demand for shipping containers and chassis. Additionally, the COVID-19 pandemic has disrupted supply chains and caused delays in the production and distribution of chassis.

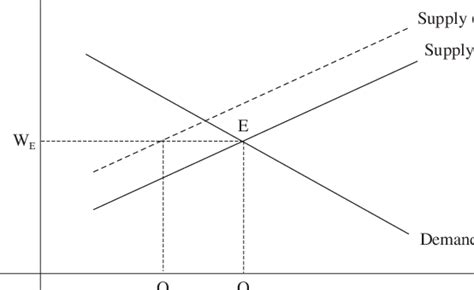

Another reason for the shortage is the imbalance in container flows.

Many containers are being imported into certain regions, while there is a lack of containers being exported from those same regions. This creates a shortage of chassis in areas where containers are being unloaded but not reloaded.

Furthermore, the consolidation of shipping lines and the closure of smaller container yards have reduced the availability of chassis. This consolidation has resulted in fewer companies owning and operating chassis, leading to a limited supply

What are the issues with chassis?

Chassis issues can be a common problem in vehicles, causing various issues and potentially compromising safety. One of the main issues with chassis is rust and corrosion. Over time, exposure to moisture, road salt, and other environmental factors can cause the chassis to rust, leading to structural weakness and potential failure. This can result in poor handling, increased vibration, and even the risk of the chassis collapsing.

Another issue with chassis is damage from accidents or collisions. If a vehicle is involved in a crash, the chassis can become bent or twisted, affecting its structural integrity. This can lead to misalignment of the wheels, uneven tire wear, and difficulty in steering and handling the vehicle.

Furthermore, chassis issues can also arise from poor maintenance and neglect.

Lack of

Will lack of parts labor extend US chassis shortages into 2024?

Labor and parts shortages in the US are causing a significant impact on the availability of chassis. Manufacturers are facing challenges in sourcing raw materials and retaining workers, which is expected to extend the chassis shortage until 2024. This means that the ongoing struggle to meet the demand for chassis throughout the country will persist for the foreseeable future.

What is happening with shipping containers?

While the Covid pandemic caused a shortage of containers, the global economy is now dealing with the opposite issue: an excess of containers. In addition to declining freight rates, recent data reveals that container depots, which are used to store containers after they are unloaded, are becoming increasingly full or already at capacity. This surplus of containers is a significant challenge for the shipping industry and has implications for global trade and logistics.

Why are shipping containers going back empty?

The immediate root cause of the spike in empty containers is the first-half inventory surge that collided with weakening consumer demand in the spring and summer.

What is causing shipping container delays?

Port congestion or port strikes can be a major source of stress for businesses involved in shipping and logistics. When there are too many containers at a port, it can lead to congestion, causing delays in the movement of goods. This congestion can be caused by various factors, such as peak seasons, unexpected events like the pandemic, or labor issues like port strikes. These delays can last for weeks, adding to the already high levels of stress experienced by businesses.

It is important for companies to find effective ways to manage this stress and minimize the impact of port congestion or strikes on their operations.

What is causing shipping delays 2023?

The COVID-19 pandemic has had a profound impact on the world’s supply chains, causing widespread disruptions and delays. Lockdown measures, a shortage of labor, and extended port turnaround times have all contributed to the worsening of global supply chain issues and shipping delays. As a result, both retailers and customers have been significantly affected by these challenges.

Why is shipping from China taking so long 2023?

The impact of Lunar New Year on shipping can be significant. During the festivities, ports, factories, and shipping companies often reduce or even suspend their operations. As a result, supply chains can experience disruptions, leading to various challenges. One such challenge is the surge in shipment volumes prior to the holidays.

Many businesses try to complete their orders before the celebrations begin, causing a high demand for shipping services. Additionally, limited capacity during this time can lead to increased rates as shipping companies struggle to accommodate the influx of shipments. These factors combined can create obstacles and delays in the shipping industry during the Lunar New Year period.

What happens to empty shipping containers?

The empty container is ready to be filled with a new shipment of cargo and transported to its intended destination. If the container is no longer needed, it may be sent to depots or ports for storage. Alternatively, it could be repurposed for empty shipping repositioning, where it is sent to a different location for future use.

What is the lifespan of a shipping container?

The lifespan of a shipping container can vary depending on various factors such as the quality of the container, maintenance, and usage. On average, a shipping container can last anywhere from 10 to 25 years. However, with proper care and maintenance, some containers have been known to last even longer.

The durability of shipping containers is due to their construction using high-quality steel.

This material is resistant to corrosion and can withstand harsh weather conditions. Additionally, shipping containers are designed to be stacked and transported, making them sturdy and reliable.

Regular maintenance is crucial in extending the lifespan of a shipping container. This includes inspecting for any signs of damage, such as rust or leaks, and promptly addressing them.

Applying protective coatings and ensuring proper ventilation can also help

Do we ship empty containers back to China?

China pays a significant amount of money to shipping carriers for exporting goods that are made in China. Interestingly, these carriers are also paid a premium to transport empty containers from America back to China. This unique arrangement highlights the importance of China’s export industry and the demand for Chinese-made products worldwide.

Is there an oversupply of shipping containers?

However, the container market has been experiencing container imbalance for several years now. Initially, during the pandemic, there was a shortage of containers, but now there is an excess. The decrease in demand and the oversupply of containers are both outcomes of the disruptions caused by the Covid-19 pandemic.

How long will container shortage last?

Some experts had previously anticipated that the shortage of containers would start to improve in 2022. They believed that an increase in container production would help alleviate the imbalances in the global supply chain.

Will shipping prices go down in 2023?

In the coming year, there is great news for importers as freight prices are expected to be adjusted and decrease by 30-40%. This is definitely a positive development, as it means that the cost of shipping goods will be more affordable. Importers will be able to save money and allocate their resources more efficiently. This decrease in freight charges is particularly beneficial for those who rely on imports for their businesses or personal needs.

It is a welcome relief for individuals and companies alike, as it will help reduce expenses and make international trade more accessible.

Is the shipping crisis getting better?

Paragraph: “Great news! The container shortage crisis that has been causing concerns in recent years is finally showing signs of improvement. We can now breathe a sigh of relief as the demand for shipping containers is slowing down and the balance of available containers is stabilizing. This positive development can be attributed to the entry of more suppliers into the market, which has led to lower prices. So, if you’ve been worried about the availability of containers, you can now rest assured that the situation is getting better.

” (106 tokens)

What did Biden do for the shipping containers?

The Biden administration has recently made a demand for Arizona to remove shipping containers that are being used to fill gaps along the border. These containers, which are stacked two high, are currently serving as a makeshift barrier in the 30-foot-high bollard border fence near the Yuma Levee Road and Morelos Dam. This move by the administration comes as part of their efforts to address the ongoing border security issues.

What is the freight outlook for 2023?

Overall, 2023 is expected to bring about significant improvements in shipping service timeliness, cost reductions, and fewer disruptions. However, the air cargo industry is currently facing a considerable amount of uncertainty. In fact, there was an 8% decrease in air cargo demand in October 2022. Despite these challenges, the industry is actively working towards finding solutions and implementing strategies to overcome these obstacles and ensure smoother operations in the future.

What is causing the shipping problems?

Supply chain disruptions can cause significant challenges for businesses, especially when it comes to shipping delays. These disruptions can stem from various global and economic factors, but they often result from issues like supply chain shortages, port congestion, freight shipping capacity restrictions, and vessel delays. Such problems can have a domino effect, impacting the timely delivery of goods and causing stress for businesses relying on smooth operations. It is crucial for companies to be aware of these potential disruptions and have contingency plans in place to mitigate their impact.

How do you solve container shortage?

How can you overcome the current container shortage? One possible solution is less-than-container-load (LCL) shipping. This method allows you to share a container with other shippers, which can help you secure capacity even if you have smaller cargo volumes. LCL shipping provides a viable solution to the problem of container shortage, making it easier for you to transport your goods.

Are shipping container prices going to come down?

Meanwhile, long-term contract rates finished 2022 about 20% lower than the pandemic peak of more than $8,000 per container, according to maritime consultancy Drewry, which expects contract rates to halve in 2023. That forecast would put rates at about $3,200, versus the pre-pandemic rate of around $1,500.

Related Article

- Why Is There A Borax Shortage?

- Why Is The Ymca So Expensive?

- Why Is The World So Broken?

- Why Is The Wisdom Teeth Vestigial?

- Why Is The Veteran Important Essay?

- Why Is The Toilet Water Yellow?

- Why Is The Toilet Water Blue?

- Why Is The Smurfs Rated Pg?

- Why Is The Sky Blue Brainly?

- Why Is The Simpsons Ride Closed?